The best ERP software for manufacturing—such as SAP S/4HANA, Oracle NetSuite, and Microsoft Dynamics 365—integrates production planning, inventory control, and financial management into a single platform.

These systems optimize supply chains, reduce waste, and provide real-time data to drive efficiency. This guide explores top-rated systems, essential features, and strategies for successful implementation.

Key Takeaways

- Top ERP systems like SAP S/4HANA, Oracle NetSuite, and Microsoft Dynamics 365 help manufacturers optimize production, enhance decision-making, and improve overall efficiency.

- Cloud-based ERP solutions offer flexibility, real-time data access, and lower upfront costs, making them ideal for both small businesses and large enterprises.

- Successful ERP implementation depends on thorough planning, employee training, and continuous performance monitoring to align with evolving business needs.

- Choosing the right ERP software ensures better customer service, improved inventory control, and long-term business growth.

Which ERP Systems Are Best for Manufacturing?

Manufacturing ERP software is more than just a tool, it’s the foundation of efficient, data-driven operations. These systems unify your inventory, supply chain, production, and financial data into one integrated platform. With the right solution, manufacturers can reduce costs, increase output, and gain real-time control over every part of their operations.

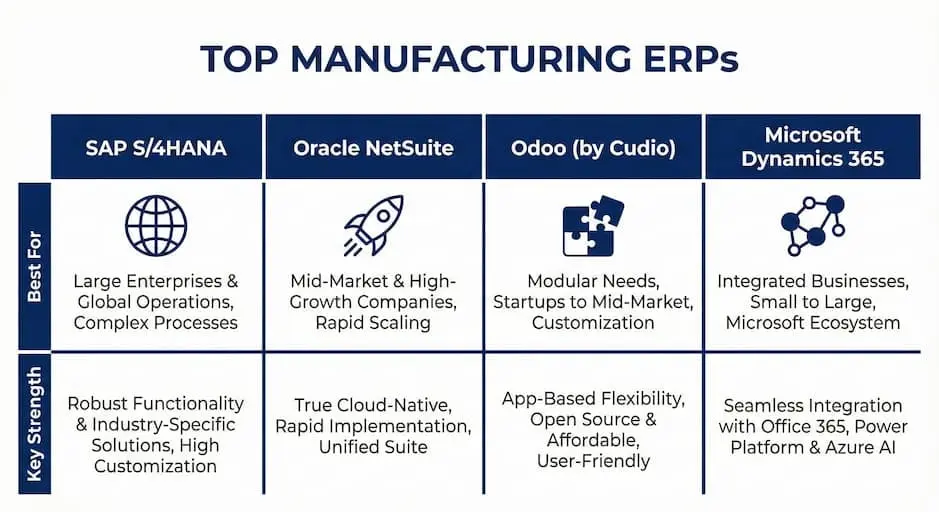

Here are three of the most reliable and widely adopted ERP platforms explicitly designed for the manufacturing sector.

SAP S/4HANA

SAP S/4HANA is the industry-standard ERP for large-scale manufacturers requiring robust, global supply chain management.

Built on a proprietary in-memory database, it processes vast datasets instantly, making it the preferred choice for 27% of the financial application market as reported by HG Insights in 2025. It supports complex, multi-site processes from procurement to production in real-time.

This architecture makes it ideal for enterprises that cannot afford latency in decision-making across international borders.

It’s widely adopted across industries such as automotive, aerospace, pharmaceuticals, and chemicals due to its depth and reliability. The system offers flexible deployment options, including cloud, on-premises, or hybrid configurations, depending on business requirements. SAP S/4HANA is ideal for businesses that demand high configurability, scalability, and global compliance features.

Key Highlights:

- Advanced supply chain and production planning tools

- Real-time data processing with predictive analytics

- Industry-specific templates for faster deployment

- Cloud, on-prem, or hybrid setup options

Best For: Large-scale manufacturing enterprises managing complex operations across global locations.

Oracle NetSuite

Oracle NetSuite is a cloud-native ERP platform that’s particularly well-suited for fast-growing manufacturing companies. It's all-in-one system includes financials, inventory management, CRM, and e-commerce capabilities. NetSuite’s modular design allows businesses to customize workflows and scale functionality as their operations grow.

Its user-friendly interface and strong automation tools help reduce manual work, allowing teams to focus on production and customer service.

The platform integrates easily with third-party applications, making it a good fit for manufacturers operating in dynamic markets. Because of its cloud-first design, businesses benefit from lower upfront costs, regular updates, and built-in security.

Key Highlights:

- Full suite covering finance, inventory, CRM, and e-commerce

- Highly customizable with strong integration options

- Lower total cost of ownership with cloud deployment

- Mobile-friendly and easy to scale

Best For: Small to mid-sized manufacturers seeking flexibility, lower upfront costs, and rapid deployment.

Odoo (Implementation by Cudio)

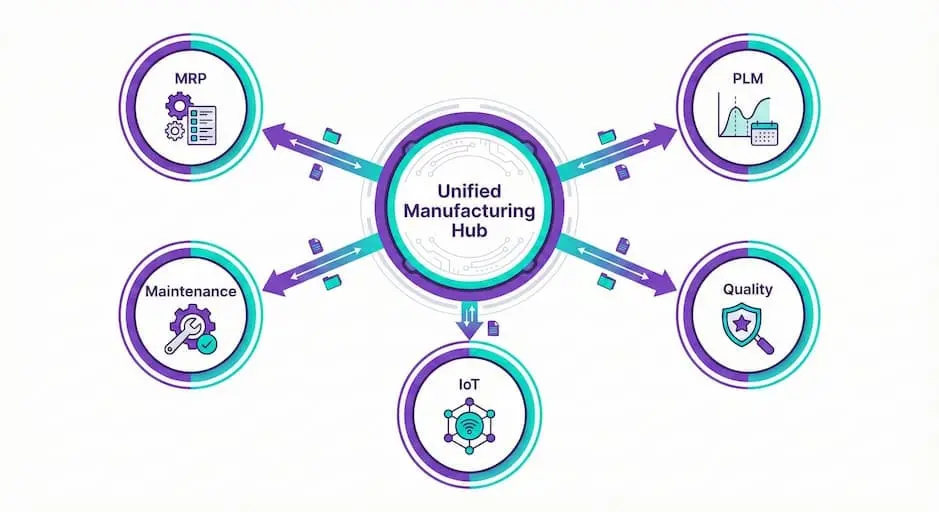

Odoo is a modular, open-source ERP that has rapidly become the disruptive alternative for manufacturers who find SAP too rigid or NetSuite too costly. With over 13 million users and a projected 25% market share of the SME sector by 2027, Odoo’s strength lies in its "app-based" architecture.

Manufacturers can start with core Manufacturing Execution Systems (MES) and Product Lifecycle Management (PLM) modules and scale out to Inventory, Quality, and Maintenance as needed.

However, the flexibility of open-source software requires expert implementation to avoid the industry's high failure rates. This is where we (Cudio) distinguish ourselves as a specialized partner. Unlike generic implementers, we focuses on "Rescue & Recovery"—turning around stalled or failed ERP projects.

Our approach combines 30+ years of tech experience with a specialized "Exclusive Trial" that allows manufacturers to test a fully configured database before committing, significantly de-risking the transition.

For manufacturers, the Odoo + Cudio combination offers the technical depth of a Tier 1 ERP—including IoT integration for shop floor automation and Master Production Scheduling (MPS)—without the seven-figure price tag or "big bang" implementation risks.

Key Highlights:

- Unified Manufacturing Hub: Seamlessly connects MRP, PLM, Maintenance, and Quality Control in one interface.

- Rescue & Recovery Specialization: We specialize in fixing failed implementations and optimizing underperforming systems.

- Exclusive Risk-Free Trial: We provide a pre-configured, data-rich trial database, unlike the standard empty Odoo sandbox.

- Real-Time Shop Floor Control: Native IoT support for automated quality checks and machine integration.

Best For: Small to mid-sized manufacturers (SMEs) requiring a custom-fit ERP without the rigidity of legacy systems, and organizations needing to recover from a failed implementation.

Microsoft Dynamics 365

Microsoft Dynamics 365 is a unified ERP and CRM solution tailored for modern manufacturers aiming to streamline operations and improve data visibility. It connects key functions such as finance, production, supply chain, and customer service into a single intelligent platform.

Manufacturers benefit from its deep integration with Microsoft tools such as Teams, Outlook, and Excel, which help teams stay productive and collaborative. Built-in AI and business intelligence features enable proactive decision-making with real-time insights.

Dynamics 365's modular architecture enables companies to scale specific functions instantly, ensuring long-term adaptability without costly system overhauls. The system is used by thousands of manufacturers worldwide and is backed by Microsoft’s continuous innovation.

Key Highlights:

- Deep integration with Microsoft ecosystem (Office, Azure, Power BI)

- Built-in AI and analytics for smarter decisions

- Scalable modules for operations, finance, and sales

- Strong mobile and cloud capabilities

Best For: Manufacturers wanting flexibility, familiar interfaces, and scalable capabilities across departments.

Why Should Manufacturers Choose Cloud-Based ERP Solutions?

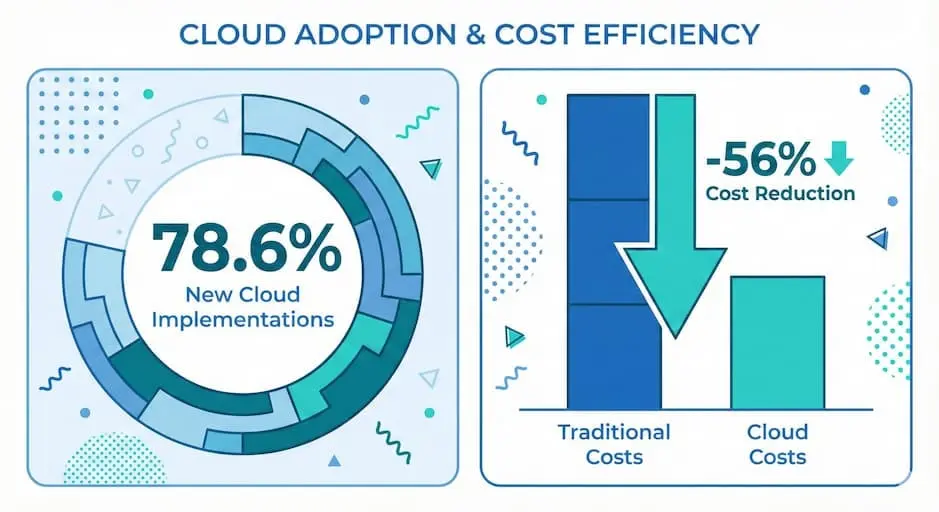

Manufacturers should choose cloud-based ERP solutions because they lower total cost of ownership (TCO) while offering superior scalability and remote accessibility.

According to Panorama Consulting’s 2024 data, 78.6% of new ERP implementations now choose cloud platforms to avoid the high capital expenditure of on-premise hardware. Cloud systems allow businesses to add modules or users instantly without physical infrastructure changes.

This flexibility enables manufacturers to adapt quickly to supply chain disruptions and maintain operations from any global location

Let’s explore the core benefits of cloud ERP systems, the value of hybrid ERP environments, and the top providers for manufacturers.

Benefits of Cloud ERP

Cloud ERP systems provide manufacturers with real-time visibility, integrated workflows, and faster time-to-value. These platforms are delivered as Software-as-a-Service (SaaS), which means companies avoid the cost and complexity of on-premise infrastructure.

Some key advantages include:

- Lower Total Cost of Ownership: Cloud ERP reduces costs by up to 56% compared to traditional systems by eliminating hardware and IT maintenance.

- Scalability: Easily add users or modules as your business grows, with no need for reinstallation or significant infrastructure changes.

- Remote Accessibility: Manage production, inventory, and sales from any device, improving response times and collaboration across locations.

- Security & Compliance: With built-in security protocols and regular updates, cloud systems help protect sensitive manufacturing and financial data.

For manufacturers aiming to stay agile and cost-efficient, cloud ERP offers a compelling return on investment and operational clarity.

Hybrid ERP Systems

Hybrid ERP bridges legacy systems and modern cloud functionality. This model allows manufacturers to keep certain operations, such as shop-floor control, on-premises while moving other functions, such as finance, HR, or procurement, to the cloud.

Benefits of a hybrid approach:

- Custom Flexibility: Choose where specific processes reside, based on control, data sensitivity, or infrastructure needs.

- Phased Implementation: Allows for gradual adoption, minimizing disruption while testing new workflows.

- Resilience: On-prem systems can maintain core operations even with connectivity issues, while cloud components provide broader scalability.

Hybrid ERP is especially valuable for manufacturers with complex production environments or regulatory constraints that require local control but still want the flexibility of the cloud.

What Features Are Essential in a Manufacturing ERP?

Modern ERP software helps manufacturing businesses enhance efficiency, improve inventory control, and streamline operations. From demand forecasting to order management, these key features support smarter, faster decisions across your entire business.

Below are the most important ERP features every manufacturing company should prioritize.

Inventory Control and Management

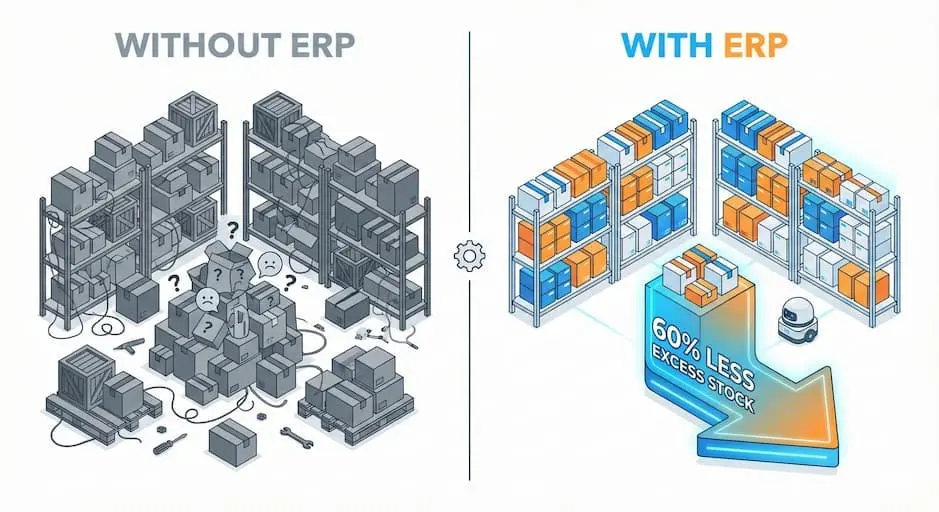

Advanced inventory control and real-time tracking are the most critical features for minimizing production waste.

Modern ERP systems track raw materials and finished goods across multiple locations, which Cavallo’s 2024 analysis shows can reduce excess stock levels by up to 60%. These tools use barcode and RFID integration to automate reordering points and valuation.

By syncing inventory directly with demand forecasts, manufacturers significantly reduce the working capital tied up in slow-moving parts.

Key features include:

- Reorder point alerts

- Stock valuation and cost tracking

- Inventory movement across sites

- Barcode and RFID integration

By syncing demand forecasting with inventory planning, ERP providers like Cudio ensure better visibility and tighter control across the supply chain.

Production Planning and Scheduling

ERP software supports more innovative production scheduling by connecting sales, inventory, and capacity planning. It enables manufacturers to efficiently allocate resources, schedule jobs, and optimize manufacturing processes using real-time data.

Core tools often include:

- Advanced order management

- Dynamic work order creation

- Labor and machine scheduling

- Bill of Materials (BOM) management

Many cloud ERP systems use AI to forecast delays, balance workloads, and adapt quickly to production changes. For example, Microsoft Dynamics integrates these capabilities with CRM systems and financial management tools to deliver a holistic manufacturing solution.

Quality Management and Compliance

Maintaining product quality is essential for customer satisfaction and brand trust. ERP vendors now offer built-in quality control features that ensure compliance with industry standards and regulatory bodies. These tools help manufacturers detect defects early, automate inspections, and generate audit trails.

Typical capabilities include:

- Inspection checklists

- Root cause analysis

- Non-conformance tracking

- Real-time dashboards

ERP technology also enables traceability across the entire manufacturing organization, which is especially critical in industries like aerospace, food, and pharmaceuticals. Companies using cloud ERP platforms benefit from streamlined compliance processes and more agile quality responses.

How Do You Successfully Implement a Manufacturing ERP?

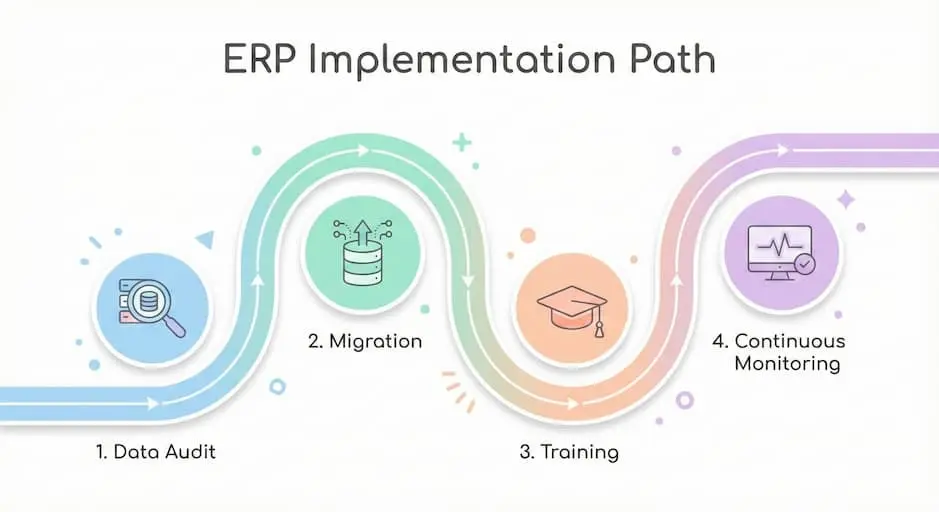

Successfully implementing an ERP system in a manufacturing organization goes beyond simply choosing the right software. It requires a carefully executed strategy that addresses technical, operational, and human elements. From planning and data migration to training and post-launch optimization, every step contributes to the project's success.

Below, we explore the critical success factors for manufacturing ERP implementation that help ensure long-term value and efficiency across your business operations.

Data Migration Strategies

A smooth data migration process is essential for ERP success. Manufacturing companies often have large volumes of legacy data spread across multiple systems. Without a clear migration strategy, businesses risk importing outdated, duplicate, or inaccurate data, which can hinder daily operations and reporting accuracy.

Steps for successful ERP data migration include:

- Conducting a full data audit to remove duplicates and outdated records

- Creating a clear roadmap for migration phases and data ownership

- Validating and cleansing data before migration into the ERP system

- Involving key stakeholders to confirm accuracy and relevance

- Performing multiple test migrations to ensure stability and compatibility

A well-planned data migration strategy reduces risk and builds a stronger foundation for real-time visibility, financial management, and better decision-making from day one.

Training and Change Management

Even the best ERP software will not yield results if users are not prepared to adopt it. Training and change management are two of the most overlooked yet critical factors for successful implementation. Your teams need to feel confident using the new system to handle manufacturing processes, inventory control, human resources, and order management.

Best practices for training and change management:

- Begin training early, ideally during system configuration

- Offer role-specific training to ensure relevance

- Use internal champions to drive engagement and answer questions

- Provide ongoing access to support resources and updated documentation

- Promote feedback loops to catch and fix adoption gaps

This is where a trusted ERP provider like Cudio can make a difference. Cudio doesn’t just configure your ERP. They deliver tailored onboarding, hands-on training sessions, and post-launch change management support. Their approach has helped clients cut onboarding time by up to 40 percent while boosting team adoption and long-term user satisfaction.

Speak to Cudio’s ERP Training Experts

Continuous Monitoring and Improvement

Implementation is not the finish line. For ERP systems to deliver sustained value, they need to be continuously evaluated, updated, and optimized. As business needs evolve, so must your ERP system. Without proper monitoring, ERP performance can degrade over time, resulting in inefficiencies and outdated processes.

Key strategies for continuous improvement include:

- Tracking KPIs post-launch to measure the effectiveness of ERP adoption

- Gathering real-time feedback from users and department leads

- Scheduling regular system audits and health checks

- Staying current with vendor updates and new ERP technology features

- Revisiting workflows quarterly to spot inefficiencies or gaps

Continuous monitoring ensures your ERP system grows with your manufacturing company, supports business growth, and remains aligned with supply chain operations, financial goals, and customer satisfaction metrics.

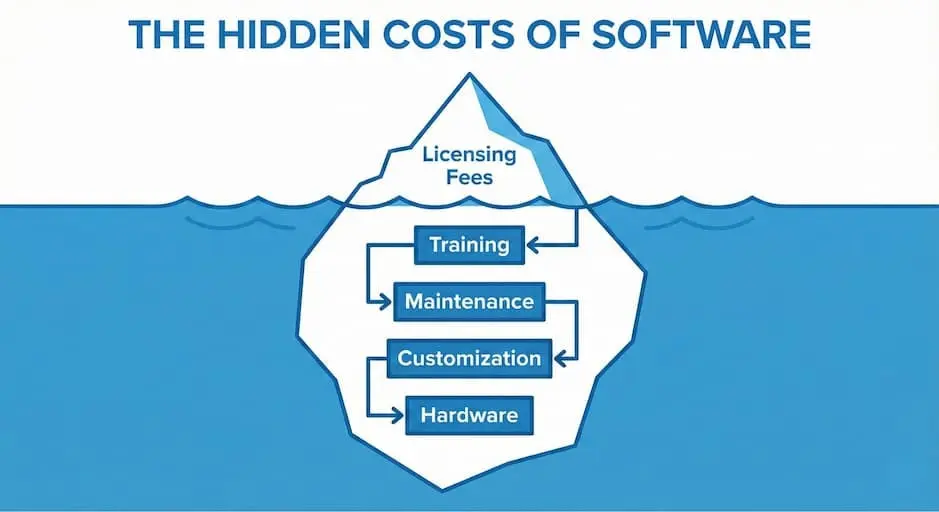

What Does a Manufacturing ERP System Cost?

Implementing an ERP system is a significant step for any manufacturing business. Understanding the complete range of costs involved is essential for long-term success. Whether you choose a cloud ERP or an on-premise deployment, careful budgeting and ROI analysis are critical for making informed financial decisions.

Enterprise resource planning plays a central role in managing business operations and supply chain activities. To make the most of your ERP software investment, it's essential to understand the actual cost of ownership and plan accordingly.

Total Cost of Ownership (TCO)

When evaluating an ERP solution, look beyond the initial purchase price. The total cost of ownership includes ongoing expenses that can impact your budget over time. These include:

- Licensing and subscription fees. Costs will vary depending on whether you select a cloud-based or on-premise ERP system.

- Implementation and customization. Expenses related to configuring the system to fit your unique manufacturing operations and workflows.

- Hardware and infrastructure. Required for on-premise or hybrid ERP systems.

- Training and onboarding. A commonly overlooked area that is essential for user adoption and effectiveness.

- Maintenance and support. Ongoing updates and technical assistance to ensure your ERP software remains secure and functional.

Considering these factors will help your manufacturing organization better understand the long-term value of ERP software and avoid budget surprises.

Budgeting for ERP Implementation

A well-planned budget helps prevent delays and cost overruns. Here’s how manufacturers can approach ERP budgeting effectively:

- Account for both direct and indirect costs. This includes licensing, training, and potential dips in productivity during transition.

- Allocate between 1 to 3 percent of annual revenue. This is a standard benchmark used by manufacturing businesses planning for ERP implementation.

- Add a contingency buffer of 10 to 15 percent. This prepares you for unexpected expenses that can occur in large ERP projects.

- Use a phased rollout when possible. Gradual implementation can control costs and reduce the impact on daily operations.

Smart budgeting ensures that your ERP for manufacturing supports your business goals without disrupting your supply chain or core business processes.

ROI Analysis

Understanding return on investment helps you measure the actual value of your ERP system. It also builds support across your team by showing the potential impact on performance and profitability. Consider these standard ROI drivers:

- Operational Cost Savings: Cavallo’s 2024 ERP Statistics report indicates that manufacturers using ERP systems save an average of 22% in operational costs by automating administrative functions.

- Better inventory control and order management. ERP software can reduce excess stock by up to 60 percent and improve order accuracy.

- Improved productivity. Automated workflows reduce manual labor and free up teams to focus on high-value tasks.

- Real-time insights. Real-time data enables accurate demand forecasting, better financial management, and faster decisions across departments.

With the right ERP solution in place, manufacturers often see ROI within 12 to 24 months. Companies using modern ERP platforms such as Microsoft Dynamics or Cudio's tailored solutions can improve financial performance, reduce implementation costs, and enhance efficiency across the entire supply chain.

Cudio works closely with manufacturers to deliver ERP systems that match their operational needs, reduce complexity, and support sustainable growth.

Book your free ERP consultation with Cudio

How Do You Select the Right ERP for Your Business?

Selecting the right ERP system is more than just going with a well-known brand. It’s about choosing a solution that aligns with your production processes, supports your manufacturing operations management, and helps manage core business processes effectively. The right ERP system can streamline business processes, reduce waste, and enhance agility in today’s competitive manufacturing landscape.

To make a smart, future-ready choice, follow this structured approach:

Assessing Business Needs

Before diving into features or researching top manufacturing ERP systems, begin with a clear understanding of your operational requirements. This step sets the foundation for selecting a solution that supports both your current and future business goals.

Here’s how to assess your needs effectively:

- Identify major challenges in your workflows, such as inventory control, order management, human resources, and process manufacturing gaps.

- Involve stakeholders from across departments including finance, IT, and production to collect a full picture of your business processes.

- Rank your priorities, whether they include real-time visibility, demand forecasting, CRM systems, or streamlined production processes.

This internal audit ensures your chosen ERP system supports your actual manufacturing operations rather than forcing you to adapt to generic software workflows.

Evaluating ERP Vendors

Once your needs are precise, it's time to evaluate ERP vendors based on their expertise, flexibility, and ability to meet the demands of your manufacturing business.

Here’s what to consider when choosing a vendor:

- Look for ERP providers with proven experience in your sector, especially those who understand the unique requirements of process manufacturing and discrete manufacturing operations.

- Assess the quality of their implementation process, training resources, and long-term customer support.

- Consider integrating with tools you already use, including cloud-based ERP systems such as Microsoft Dynamics.

If you're looking for more than just software, Cudio offers personalized support and end-to-end services. Trusted by manufacturing companies across North America, Cudio specializes in ERP implementation, system recovery, and cloud-based ERP solutions tailored to complex supply chain environments.

Technological Advancements

Modern ERP technology is rapidly evolving, and your chosen platform should be ready for what’s next.

- Look for systems that leverage AI, IoT, and predictive analytics to support smarter operations and enhanced efficiency.

- Modular architectures and composable ERP systems allow for flexible scaling as your manufacturing business grows.

- Consider solutions that prioritize security, ESG compliance, and mobile accessibility to future-proof your ERP investment.

Choosing an ERP solution that aligns with these trends not only supports your current workflows but also positions your business for long-term success.

Summary

Choosing the right ERP system for your manufacturing business is more than just a software decision. It’s a strategic investment in organizational efficiency, operational agility, and long-term competitiveness. From production planning and inventory replenishment to production scheduling and quality assurance, the right ERP solution helps align your technology with your operation's real needs.

Modern ERP platforms go beyond basic automation. They offer real-time insights, advanced analytics, and even tools for predictive maintenance, giving your sales teams and managers the visibility they need to make smarter, faster decisions. When well-implemented, ERP systems can dramatically boost productivity, reduce waste, and improve customer satisfaction across the board.

But true success comes from more than just installing software. It requires thoughtful planning, team alignment, and a long-term commitment to process improvement.

If you're ready to streamline operations and maximize results, Cudio helps manufacturers implement ERP systems designed for growth, from first consult to post-launch optimization.

Talk to Cudio’s ERP experts today

Frequently Asked Questions

What ERP do most companies use?

Most companies prefer NetSuite as their top ERP choice, followed by Dynamics 365 Business Central, Odoo ERP, SAP ERP, and Workday. Each of these systems offers unique features that cater to various business needs.

What are the top three vendors in the ERP market?

The top three vendors in the ERP market are SAP, Oracle NetSuite, and Microsoft Dynamics 365. These companies are recognized for their comprehensive solutions and significant market presence.

What are some expected benefits of properly selecting and designing an ERP system?

Properly selecting and designing an ERP system can lead to significant improvements in efficiency, timely deliveries, and overall revenue, while also minimizing delivery times, costs, quality issues, and inventory levels. This streamlined approach ultimately enhances organizational performance.

Why is choosing the right ERP methodology important?

Choosing the proper ERP methodology is vital for successful implementation as it aligns with business needs and minimizes the risk of failure. This strategic decision leads to better adherence to best practices and ultimately enhances the overall effectiveness of the ERP system.

What is the main goal of using an ERP system?

The primary goal of using an ERP system is to enhance business efficiency and adapt swiftly to changes in a competitive landscape. By streamlining processes, organizations can respond effectively to market demands.